Environmental Testing

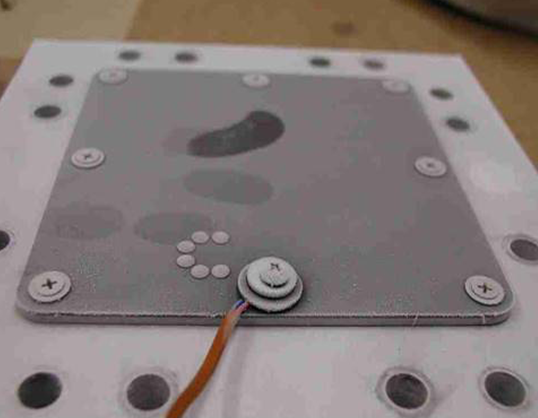

At Haigh-Farr, we take great pride in our hardware’s ability to survive the harshest of environmental conditions while meeting or exceeding the RF performance needs of our customers. Haigh-Farr products have an excellent track record of surviving and performing in many extreme environments including deep space, high velocity/high aero, and range safety applications. We accomplish this by running our delivered goods through a robust test program. In the majority of cases, we can do all of our testing in-house using Haigh-Farr equipment and expertise, and running on a customer-driven, Haigh-Farr controlled schedule.

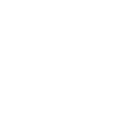

Regarding Haigh-Farr’s in-house capabilities, the list of environmental test equipment is significant, and continues to grow. Haigh-Farr currently has 8 thermal chambers, a thermal vacuum chamber specifically designed for the testing of antennas, and two UD T2000 shakers used for not only random and sine vibration but simulated shock as well. Also, Haigh-Farr has 2 humidity chambers and a resonant-beam shock system for higher shock level requirements. Finally, we have the ability to merge or combine testing capabilities such as vibration and shock testing at flight temperatures.

In summary, Haigh-Farr’s ability to test customer hardware using our equipment run by our team of experts driven by the customer’s schedule means robustly screened product delivered in a timely fashion.